1801 INC

1801 Inc.

1801 Inc. the forefront of global industrial machinery solutions. Our company is a world leader in providing complete, end-to-end services for sourcing, investigating, procuring, transporting, installing, training, and running operational trials for all types of large industrial equipment. With a presence on every continent and a proven track record across diverse industries, we empower businesses to grow by seamlessly delivering, integrating, and optimizing industrial assets anywhere in the world.

At the core of our service is a commitment to precision, safety, and reliability. Whether you are looking to upgrade manufacturing capabilities, expand production, or set up greenfield operations, our multidisciplinary team orchestrates every phase—from strategic sourcing to onsite commissioning—with unwavering attention to detail. We understand the high stakes of industrial investment. That’s why we leverage our global network of suppliers, logistics experts, engineers, trainers, and project managers to ensure your assets arrive on time, installed to the highest standards, and ready to perform from day one.

We Are

Founded by seasoned industry professionals with decades of international project experience, our company was established to address the most critical pain points in the industrial equipment lifecycle. We recognized that traditional approaches—fragmented between different vendors for sourcing, transportation, installation, and commissioning—caused cost overruns, schedule delays, and operational headaches.

Our mission: to become the trusted single-source provider for comprehensive industrial machinery solutions globally.

Our Journey and Values

Our company’s inception was rooted in a passion for enabling industrial progress through expertise, integrity, and innovation. Over the years, we have assembled a diverse team of mechanical engineers, procurement specialists, logistics coordinators, certified trainers, and project managers who have successfully executed hundreds of complex machinery projects across globe.

What unites us is a set of uncompromising values:

– Customer Focus:

Every project is driven by your success criteria—from performance metrics to sustainability and safety targets.

– Quality Without Compromise:

We exceed international standards (ISO, CE, ANSI) in every phase—sourcing, installation, and operations.

– Innovation:

We pursue continuous improvement in our processes, leveraging digital tools for project tracking, remote inspections, and real-time logistics monitoring.

– Transparency:

Our clients benefit from 24/7 project visibility and proactive communication at every stage.

Our successful track record includes supporting manufacturers, greenfield operations for emerging market leaders, and ambitious expansion projects for family-owned enterprises. The testimonials and repeat business we receive are a testament to our unwavering commitment to excellence.

We Care

In an industry where equipment failure or project overruns can result in multimillion-dollar losses, our company stands apart through guaranteed reliability, fully integrated services, and a global reach unmatched by ordinary vendors.

Key Differentiators

– Single-Source Accountability:

Eliminate the risks and finger-pointing of fragmented vendor management; we are your end-to-end partner from feasibility to final acceptance.

– Global Sourcing Agility:

Our local presence in major industrial hubs worldwide enables access to best-in-class technology and competitive pricing, even during supply shocks or trade disruptions.

– Cutting-Edge Logistics:

Expertise in complex, multimodal transport and customs management for ultra-heavy and high-value shipments ensures your equipment arrives on time, intact, and compliant.

– Onsite Engineering Excellence:

Our installation teams are trained to rigorous international standards, with a zero incident and zero rework philosophy.

– Comprehensive Post-Installation Support:

We don’t disappear after installation—our support includes operator training, preventive maintenance planning, spare parts management, and performance monitoring.

– Digital Project Management:

Secure, cloud-based project tracking keeps clients informed in real time, promoting transparency and fast decision-making at every project phase.

The Value Proposition

By managing the complete equipment lifecycle, our clients consistently achieve:

– Accelerated, predictable project timelines

– Reduced total cost of ownership

– Maximized equipment uptime and process safety

– Full compliance with international and local regulations

– Improved workforce competency and retention through certified skills transfer

We are more than a machinery vendor—we are a global partner in your industrial success, proven time and again across continents and market segments.

We Do

Our 7-Step Comprehensive Process:

1. Initial Consultation and Needs Assessment

Every engagement begins with a deep-dive consultation to understand your objectives, technical requirements, site conditions, project timelines, and regulatory constraints. Our engineers and project managers work closely with your team to define specifications and identify unique risk factors or opportunities for value optimization.

2. Global Machinery Sourcing and Investigation

Leveraging our global supplier relationships and dedicated sourcing offices, we scan the worldwide marketplace to identify machinery that matches your needs—considering factors such as quality, cost, lead times, after-sales support, and compliance certifications. We conduct thorough due diligence, including supplier audits, equipment inspections, and sample testing either virtually or onsite.

3. Procurement and Negotiation

Once a preferred supplier and equipment solution are identified, our procurement team manages the entire acquisition process. This includes commercial negotiations, contract drafting with protective clauses, payment milestone structuring, and coordination with insurers and financial partners to minimize risk.

4. International Logistics and Transportation

With machinery often oversized and extraordinarily valuable, transportation is planned and executed with military precision:

– Route surveys and risk assessments for oversized or heavy cargo

– Coordination with global logistics providers and customs agents

– Use of specialized lifting, rigging, and securing equipment

– Real-time shipment tracking and contingency planning for delays or disruptions.

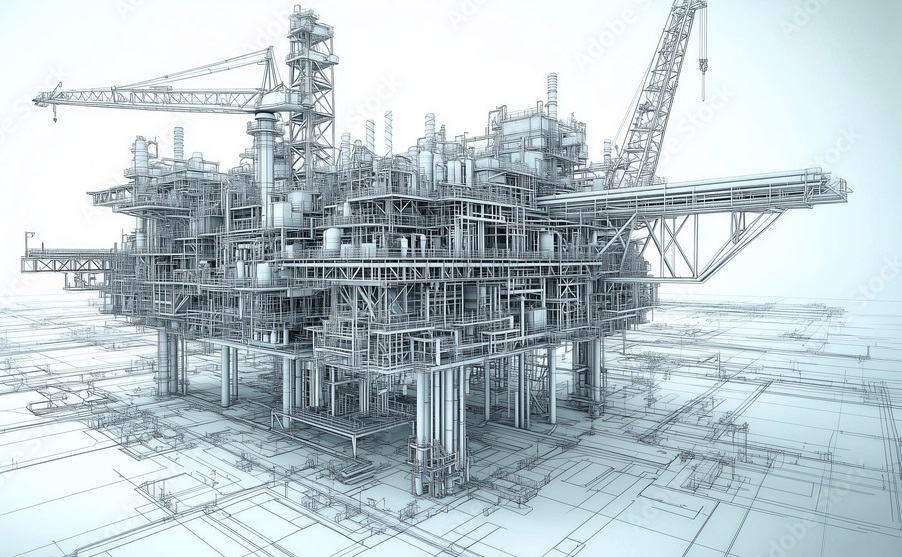

5. Site Preparation and Installation

Prior to arrival, our team coordinates with local stakeholders to ensure the site is fully prepared—power, foundations, access, and permits. Installation is executed by teams of certified engineers and technicians, strictly adhering to manufacturer and regulatory guidelines, as well as customized site safety plans.

6. Operator Training and Skills Transfer

Training is customized to your workforce and the equipment’s complexity. It may include classroom sessions, hands-on workshops, virtual simulations, and official certification programs. Our trainers—often manufacturer-certified—ensure skills transfer for safety, efficiency, troubleshooting, and preventive maintenance.

7. Testing, Trial Runs, and Handover

Comprehensive testing protocols verify mechanical performance, automation systems, product quality, and safety interlocks under real-world conditions. Any issues are resolved jointly with your team. Only when all acceptance criteria are met do we formally hand over the equipment, complete with documentation, warranties, and a post-project review.

| Phase | Description | Activities |

|---|---|---|

| Assessment | Understand client goals and constraints | Site visits, requirements gathering, feasibility studies |

| Sourcing & Audit | Identify, investigate, and validate equipment suppliers | Supplier audits, demo visits, documentation collection |

| Procurement | Negotiate and execute acquisition | Contract negotiation, compliance, risk management |

| Logistics | Plan and execute shipment and delivery | Transport planning, customs clearance, shipment monitoring |

| Installation | Prepare site and install equipment | Site prep, equipment unloading/setup, alignment |

| Training | Train operators and maintenance staff | Classroom, hands-on, digital learning, certifications |

| Testing & Trials | Ensure operational readiness and handover | Trial production runs, QC inspections, documentation, client signoff |

Every stage outlined in this workflow is handled with precision, transparency, and a relentless focus on success criteria. Our project management methodology combines classical best practices (such as Gantt chart scheduling and critical path analysis) with agile responses to changing conditions on the ground, ensuring your project stays on track and delivers measurable business value.

We Deliver

We source, integrate, and support a vast array of industrial machinery across all major sectors, from traditional heavy equipment to the most advanced automated manufacturing systems. Our expertise includes:

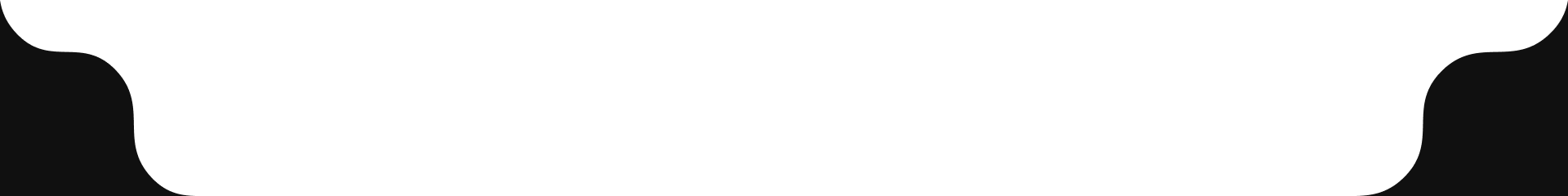

1. Manufacturing Equipment

– CNC Machines: Automated precision tools for milling, turning, and cutting

– Injection Molding Machines: For plastics, composites, and specialty materials

– Robotics and Automation Cells: Flexible, programmable solutions for assembly, welding, and packaging

– Presses (Hydraulic/Mechanical): Power operations in metalworking and forming.

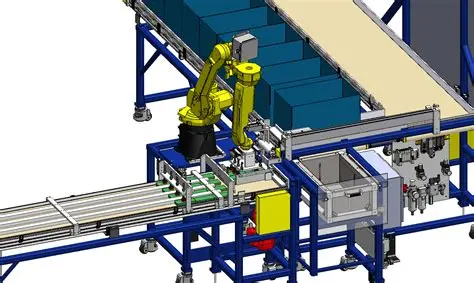

2. Process Industry Equipment

– Chemical Reactors and Mixers: For continuous or batch chemical processes

– Heat Exchangers, Boilers, and Kilns: Thermal process machines for energy and materials industries

– Centrifuges and Separators: For solid/liquid/gas separation in pharmaceuticals, food, and mining.

3. Construction and Earthmoving Machinery

– Excavators, Bulldozers, Loaders: For infrastructure, mining, and earthworks

– Cranes and Lifting Equipment: For material handling and vertical construction

– Concrete and Asphalt Plants: Modular equipment for onsite materials production.

4. Energy and Power Generation Equipment

– Gas and Steam Turbines

– Diesel and Gas Gensets

– Renewable Energy Systems: Wind turbines, solar panel installations, and supporting infrastructure

5. Packaging and Material Handling Systems

– Automated Conveyor Systems

– Palletizers, Wrappers, and Cartoning Machines

– Sorting and Warehouse Automation

6. Specialized and Custom Machinery

– Food Processing Lines: For bakery, dairy, grains, and beverage sectors

– Textile and Paper Machinery

– Heavy Forging Presses and Rolling Mills.

| Type | Industry Applications | Use Cases |

|---|---|---|

| CNC & Automated Manufacturing | Automotive, Aerospace, Electronics, Medical Devices | Engine blocks, circuit boards, medical instruments |

| Injection Molding & Plastics Processing | Packaging, Consumer Products, Automotive | Bottles, dashboards, electronic housings |

| Bulldozers, Excavators, Earthmovers | Construction, Mining, Infrastructure | Site preparation, ore extraction, road building |

| Boilers, Reactors, Centrifuges | Chemicals, Energy, Pharmaceuticals, Food | Chemical synthesis, sterilization, materials separation |

| Automated Packaging & Material Handling | Food & Beverage, Textiles, E-Commerce, Logistics | Bottling, carton packing, order fulfillment |

| Wind Turbines, Generators, Gensets | Power Generation, Renewables, Industrial Utilities | Electricity generation, backup/emergency power |

| Heavy Forging, Rolling Mills | Metals, Shipbuilding, Rail, Large-Scale Structures | Steel beams, ship hull plates, railroad rails |

This table provides only a sample: our reach extends to virtually every industrial sector, with tailored sourcing and integration for unique applications. Rapid advances in automation, digitalization, and electrification mean today’s “standard” equipment can be customized for highly specific client needs—an area where our investigative and engineering capabilities deliver maximum value.

Why Us?

In an industry where equipment failure or project overruns can result in multimillion-dollar losses, our company stands apart through guaranteed reliability, fully integrated services, and a global reach unmatched by ordinary vendors.

Key Differentiators

– Single-Source Accountability: Eliminate the risks and finger-pointing of fragmented vendor management; we are your end-to-end partner from feasibility to final acceptance.

– Global Sourcing Agility: Our local presence in major industrial hubs worldwide enables access to best-in-class technology and competitive pricing, even during supply shocks or trade disruptions.

– Cutting-Edge Logistics: Expertise in complex, multimodal transport and customs management for ultra-heavy and high-value shipments ensures your equipment arrives on time, intact, and compliant.

– Onsite Engineering Excellence: Our installation teams are trained to rigorous international standards, with a zero incident and zero rework philosophy.

– Comprehensive Post-Installation Support: We don’t disappear after installation—our support includes operator training, preventive maintenance planning, spare parts management, and performance monitoring.

– Digital Project Management: Secure, cloud-based project tracking keeps clients informed in real time, promoting transparency and fast decision-making at every project phase.

The Value Proposition

By managing the complete equipment lifecycle, our clients consistently achieve:

– Accelerated, predictable project timelines

– Reduced total cost of ownership

– Maximized equipment uptime and process safety

– Full compliance with international and local regulations

– Improved workforce competency and retention through certified skills transfer

We are more than a machinery vendor, we are a global partner in your industrial success, proven time and again across continents and market segments.

Let's Transform Your Business with Expert IT Solutions